Today, we’re thrilled to announce that we have approved the Bee for mass production.

This summer, the Bee Maps team tested several dozen Bee dashcam prototypes to make sure we had chosen the best components for the job.

With more than 350 million kilometers of roads mapped by the HDC and the HDC-S, we knew what it would take to make the Bee our best mapping machine yet. And it is.

Although shipping did not start in Q3 as targeted when we opened preorders in February, we are just weeks away from shipping the first 3D-printed dashcams to public testers.

And we have high confidence we will start shipping the final, production version of the Bee to order-holders in Q4. (Note: That’s the start of production. There are currently tens of thousands of units on preorder.)

We take our commitment to our customers seriously. We regret that shipping will start a bit later than we initially thought it would. We are moving as quickly as we can to get you a great dashcam without any compromises on mapping performance.

Taking a little bit of extra time to iterate on our earlier prototypes has made the Bee better. We’re moving to mass production with conviction the Bee will be the game-changing mapmaking machine we imagined, giving the Hivemapper Network even stronger capabilities to meet the needs of the world’s largest map data customers.

Manufacturing Status

Before assembly of the production Bee begins, we plan to produce a few hundred testing units for employees, map data customers and members of our community testing groups.

These units will be the exact same as the production version, except they’ll have an unpolished 3D-printed housing. We will start producing these 3D-printed units for public testers in October.

As mentioned above, we have high confidence we will start shipping the production version of the Bee in Q4. The main reason we can’t start ramping manufacturing today is that we’re waiting for the final version of some injection molded and cast parts that we couldn’t order until we cleared the Bee for mass production.

Hardware is hard. Timelines can slip for unexpected reasons. However, the key thing is that we’ve validated the performance of the Bee design and hardware that we intend to scale, and we couldn’t be happier with its performance.

It is still too early to project exact shipping dates for customers’ individual orders. However, we and our manufacturing partner are investing in automation to increase the throughput of the Bee assembly line to a significantly higher level than we ever managed with the original HDC or HDC-S dashcams. We will be able to provide far more frequent and more meaningful updates moving forward about expected ship dates, especially as production begins and we gain a better understanding of the pace of the production ramp.

If you have any questions about your order, please contact us at [email protected].

If you don’t want to keep waiting, we completely understand. As always, we are happy to provide a full refund. You will have a chance to buy a Bee in the future after we finish fulfilling preorders and have inventory available for immediate shipment.

Positional Accuracy

Beyond sharing the latest on shipping timelines, we wanted to share a couple examples of milestones we’ve achieved that will make the Bee such a game-changing device.

The first milestone is on positioning. Some crowdsourced mapping developers make the argument that you can’t achieve great positional accuracy without a supplementary service to correct the position provided by the GPS/GNSS satellites.

This debate reminds us of the debate over lidar in autonomous vehicles. For years, some developers insisted autonomous vehicles couldn’t drive without lidar – even though humans manage pretty well without it. Tesla, with its Full Self-Driving product, subsequently showed that cars without lidar can navigate the world in virtually any scenario. More and more developers are forgoing lidar and moving to camera-based solutions.

We feel similarly about GPS/GNSS correction services such as real-time kinematics, or RTK. It is helpful technology, but it typically requires you to install an additional piece of hardware mounted on the roof and pay an additional monthly service fee beyond your cellular bill to access a network of fixed hardware devices. The vision of Hivemapper is to make mapping passive and effortless. This is too much friction for making mapping mainstream.

So, to help make the Bee a game-changing mapping machine, we’ve invested in a higher-end onboard GPS/GNSS chip and antenna than the makers of smartphones and consumer dashcams would ever choose to include.

Rather than relying on RTK correction services for further improvements, we are complementing that GPS/GNSS signal with advanced techniques we’ll explain in detail in a later post.

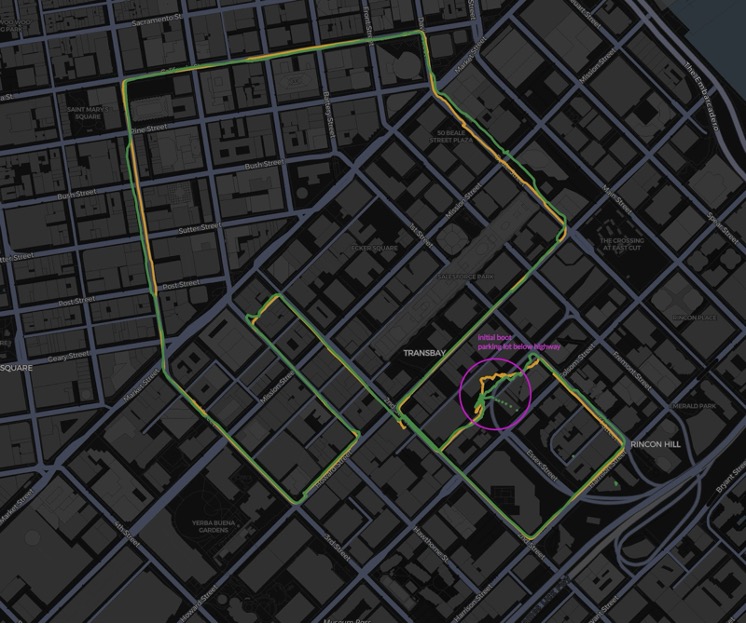

The results are exceptional. In the image above, the green line represents an exterior-mounted device relying on RTK corrections, while the yellow line represents an interior-mounted Bee dashcam with no corrections. It’s worth noting this is an area of downtown San Francisco with countless “urban canyons” between skyscrapers. That is one of the most challenging environments for GPS/GNSS technology, which relies heavily on a clear view of the sky.

We are confident the Bee will deliver the best positioning of any mapping dashcam on the market – and may even be able to provide corrections to other connected devices.

Stereo Camera

As a piece of hardware, the Bee is more like an automotive ADAS module than a dashcam.

The main central camera lens is flanked by stereo cameras. Like human eyes, these stereo cameras are far enough apart for the Bee to generate a fully immersive 3D scene, allowing us to pinpoint objects with incredible precision in 3D space.

There are many approaches to improving positional accuracy, as discussed in the previous section. But improving the positioning of the device itself is only half the battle.

Building a map isn’t about establishing the location of the cameras that mapped the world – that isn’t what customers care about. They care about the location of objects in the real world.

These images show the performance of the stereo cameras traveling at highway speeds without blur, allowing the creation of an accurate depth map to position objects on the edge.

With more onboard computing power than our original dashcam, Map AI is able to do this work on the edge with capacity left over for future capabilities.

The Team Behind the Bee

The reason all these improvements are possible is the talented team working on the Bee.

Our first, second and third priorities are investing in the products and end-to-end processes that allow us to build valuable map products for end users. That is the only source of sustainable long-term value for a project such as Hivemapper, and that is where we will always focus.

Bee Maps has invested heavily in engineering capabilities since launching the original HDC. So far in 2024, we’ve brought in top engineers from universities such as UC-Berkeley, Stanford and Carnegie Mellon, with experience at companies such as Google, Lyft and Scale AI, to join the already talented team that got our first dashcams out into the world.

We’ve also deepened our partnerships with skilled design and manufacturing partners that specialize in advanced computer vision systems as well as the robotic vision specialist Luxonis, which assisted with design and development. They have been instrumental in getting this game-changing dashcam ready for production.

Now it’s time to ramp up production. We have tens of thousands of dashcams to ship. We know you’re itching to get out there and map the world.

We won’t slow down until we get you a Bee.

Follow us on X or Try Bee Maps for Free.